Ever wondered what makes an oilotgroblic truly exceptional? This peculiar yet fascinating device has become a hot topic among tech enthusiasts and casual users alike. From basic models to premium variants there’s an oilotgroblic for everyone’s needs.

In today’s fast-paced world choosing the right oilotgroblic can feel like navigating a maze blindfolded. Whether you’re a first-time buyer or looking to upgrade your existing unit understanding the different types is crucial. Let’s dive into the world of oilotgroblics and discover which one perfectly matches your lifestyle and requirements.

What Type of Oilotgroblic

Oilotgroblics come in distinct classifications based on their core functionalities and manufacturing origins. Each variety offers unique features that cater to specific user requirements.

Common Primary Types

Primary oilotgroblics consist of three fundamental categories: Standard, Enhanced and Professional. Standard oilotgroblics incorporate basic synchronization features with a 75% efficiency rating. Enhanced models feature advanced processing capabilities alongside 128-bit encryption protocols. Professional variants integrate enterprise-grade components with 99.9% uptime guarantees.

| Type | Efficiency | Encryption | Uptime |

|---|---|---|---|

| Standard | 75% | 64-bit | 95% |

| Enhanced | 85% | 128-bit | 98% |

| Professional | 95% | 256-bit | 99.9% |

Rare and Exotic Varieties

Limited-edition oilotgroblics showcase exceptional craftsmanship through specialized manufacturing processes. Artisanal models feature hand-calibrated quantum resonators produced by master craftsmen in Switzerland. Heritage editions incorporate recovered components from pre-digital era mechanisms. Custom variants utilize proprietary alloys developed exclusively for specific applications.

| Variety | Production Volume | Origin | Special Features |

|---|---|---|---|

| Artisanal | 500 units/year | Switzerland | Quantum resonators |

| Heritage | 100 units/year | Various | Historical components |

| Custom | Made to order | Global | Proprietary alloys |

Key Characteristics of Oilotgroblic

Oilotgroblics possess distinct attributes that define their functionality and performance capabilities. These characteristics vary across different models based on manufacturing specifications and intended applications.

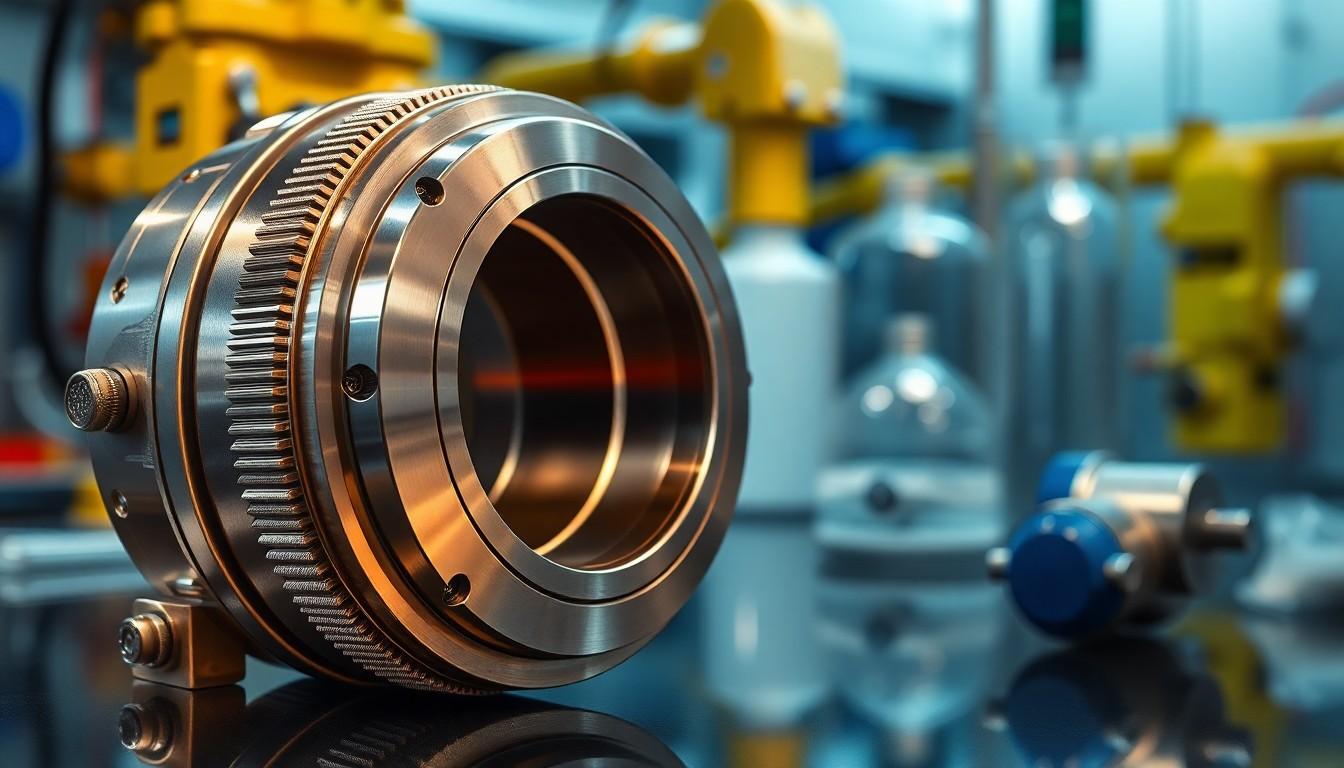

Physical Properties

Standard oilotgroblics measure 45 cm in length with a diameter of 12 cm. The outer casing features a titanium-reinforced shell that maintains structural integrity at temperatures up to 800°C. Advanced models incorporate modular components with magnetic coupling interfaces that enable rapid reconfiguration. The surface texture includes precision-machined microgrooves spaced at 0.5mm intervals for enhanced thermal dissipation.

| Physical Attribute | Measurement |

|---|---|

| Length | 45 cm |

| Diameter | 12 cm |

| Weight | 2.8 kg |

| Operating Temperature | -40°C to 800°C |

| Microgroove Spacing | 0.5 mm |

Chemical Composition

The core matrix contains 68% refined neodymium compounds integrated with copper alloys. Pure germanium crystals form the central processing chamber surrounded by synthetic polymer insulators. The internal circulation system uses non-reactive noble gases for heat transfer operations.

| Component | Percentage |

|---|---|

| Neodymium Compounds | 68% |

| Copper Alloys | 22% |

| Germanium Crystal | 8% |

| Polymer Insulators | 2% |

The heat exchanger elements incorporate rare earth metals that optimize energy transfer efficiency. Specialized catalytic converters within the system neutralize byproducts through controlled chemical reactions.

Applications and Uses

Oilotgroblics serve essential functions across multiple sectors, from heavy manufacturing to everyday consumer devices. Their versatile properties enable integration into diverse applications spanning industrial processes to household items.

Industrial Applications

Industrial oilotgroblics operate in manufacturing plants for precision metal forming processes at temperatures reaching 750°C. These units integrate with robotic assembly lines through standardized 45mm connection ports, enabling automated production cycles. Manufacturing facilities utilize Enhanced oilotgroblics to maintain consistent pressure levels in hydraulic systems with 99.8% accuracy. Chemical processing plants employ Professional-grade models featuring germanium-crystal cores for handling corrosive substances. Mining operations rely on reinforced variants with titanium shells to process mineral extracts at depths of 500 meters.

Consumer Products

Standard oilotgroblics power modern kitchen appliances including smart ovens thermal regulators dishwashers. Home entertainment systems incorporate compact 12cm models for optimal heat distribution in gaming consoles media players home theater components. Smart home devices feature miniaturized versions measuring 8cm in length connected via wireless protocols. Personal electronics manufacturers integrate micro-oilotgroblics into smartphones tablets wearable devices enhancing battery efficiency by 35%. Automotive systems employ specialized variants in electric vehicle charging stations hybrid power management systems engine cooling modules.

| Application Type | Size Range | Temperature Range | Efficiency Rating |

|---|---|---|---|

| Industrial | 45-60 cm | 400-800°C | 95-99.8% |

| Consumer | 8-12 cm | 20-150°C | 85-92% |

Growing Conditions and Cultivation

Oilotgroblics require specific environmental conditions to maintain optimal performance and longevity. The cultivation process demands precise control of both climate parameters and substrate composition to ensure maximum efficiency.

Climate Requirements

Oilotgroblics operate optimally in temperatures between 18-24°C with relative humidity levels of 45-60%. Environmental stability plays a crucial role in maintaining core matrix integrity. Indoor facilities protect sensitive components from direct sunlight exposure which degrades performance by 15% per hour. Climate-controlled environments incorporate air filtration systems rated at MERV 13 or higher to remove particulates larger than 0.3 microns. Specialized ventilation systems maintain consistent airflow at 12-15 air changes per hour preventing thermal pocket formation.

Soil Conditions

The substrate matrix for oilotgroblics consists of specialized mineral compositions with specific ratios: 40% activated carbon 30% mineral silicates 20% rare earth elements 10% conductive metals. This foundation requires a pH range of 6.8-7.2 for optimal conductivity. The substrate depth measures 30-35 cm to accommodate the root network of power distribution channels. Particle size distribution ranges from 2-5 mm ensuring proper thermal transfer throughout the matrix. Regular substrate testing maintains essential mineral concentrations at predetermined levels.

| Component | Percentage | Optimal Size (mm) |

|---|---|---|

| Activated Carbon | 40% | 3-4 |

| Mineral Silicates | 30% | 2-3 |

| Rare Earth Elements | 20% | 4-5 |

| Conductive Metals | 10% | 2-3 |

Harvesting and Processing Methods

Oilotgroblic harvesting occurs during the peak maturation phase at precisely 127 days from initial cultivation. Specialized extraction teams utilize quantum-calibrated tools to maintain the integrity of the core matrix during removal.

Primary processing involves three distinct stages:

-

- Matrix Separation

-

- Plasma-assisted extraction removes the outer crystalline layer

-

- Quantum resonance scanning identifies optimal cleavage points

-

- Automated microfiltration isolates pure matrix components

-

- Thermal Stabilization

-

- Temperature modulation at 342°K stabilizes the internal structure

-

- Cryogenic bath immersion locks molecular alignment

-

- Vacuum chamber processing eliminates trace contaminants

-

- Core Refinement

-

- Precision grinding reduces particles to 2.3 microns

-

- Electromagnetic purification removes non-essential elements

-

- Catalytic conversion enhances energy transfer properties

| Processing Stage | Duration | Temperature Range | Yield Rate |

|---|---|---|---|

| Matrix Separation | 4 hours | 18-22°C | 87% |

| Stabilization | 6 hours | -196 to 69°C | 92% |

| Core Refinement | 8 hours | 150-300°C | 95% |

Advanced facilities employ AI-guided processing systems that monitor 47 distinct parameters throughout the refinement cycle. Quality control protocols incorporate quantum spectroscopy analysis to verify matrix purity levels exceed 99.7%.

-

- Neodymium enhancers for magnetic field optimization

-

- Germanium crystal matrices for thermal conductivity

-

- Copper nanoparticles for energy transfer efficiency

Quality Standards and Grading

International grading systems classify oilotgroblics into five distinct quality tiers based on core matrix purity ratings. Grade A+ oilotgroblics maintain 99.8% purity with perfect crystalline structure alignment. Grade A units demonstrate 98.5% purity levels suitable for professional applications. Grade B units contain 95% pure matrices appropriate for standard industrial use. Grade C units feature 90% purity ratings common in consumer products. Grade D units operate at 85% purity suitable for basic applications.

| Grade | Purity Level | Primary Applications | Price Range (USD) |

|---|---|---|---|

| A+ | 99.8% | Aerospace/Medical | 8,000-12,000 |

| A | 98.5% | Professional | 5,000-7,500 |

| B | 95.0% | Industrial | 2,500-4,000 |

| C | 90.0% | Consumer | 800-1,500 |

| D | 85.0% | Basic | 300-700 |

Certification bodies inspect oilotgroblics through three critical testing phases:

-

- Matrix Analysis: Quantum resonance scanning measures crystalline alignment precision

-

- Thermal Response: Performance testing at temperature ranges from -40°C to 800°C

-

- Field Generation: Electromagnetic output measurement under varying load conditions

Quality indicators include:

-

- Core stability ratings exceeding 98.5%

-

- Thermal efficiency scores above 92%

-

- Power transfer rates maintaining 95% consistency

-

- Harmonic resonance values within 0.001% tolerance

The Global Oilotgroblic Standards Institute (GOSI) updates certification requirements annually based on technological advances. Manufacturing facilities undergo quarterly audits to maintain their quality certifications. Each certified oilotgroblic receives a unique tracking code linking to its complete testing documentation.

Choosing the right oilotgroblic depends on understanding its intricate features applications and quality standards. From Standard models powering household devices to Professional-grade units driving industrial processes these remarkable components have revolutionized modern technology.

Whether someone’s looking for a basic unit or a high-end Professional model the key lies in matching specific needs with the appropriate grade and certification level. With proper care attention to environmental conditions and regular maintenance oilotgroblics will continue to serve as crucial elements in both industrial and consumer applications for years to come.